- K.K. Nagar, Chennai - 600 078

GOODSEAL Gaskets are made out of alternate plies of preformed metal and soft Non-Metallic filler. The metal winding of GOODSEAL gasket is formed into a "CHEVRON" coniguration allowing superior resiliency and selfadjustment when compared to conventional gaskets. The density of the GOODSEAL gasket can be varied to meet virtually any requirement. Electronic Controls on NIP specially fabricated machines assure High Quality Precision Welding, with equal spacing.

GOODSEAL Type GGP/SPW-WR construction a spiral wound sealing section with a solid metal outer ring. These self-centering gaskets with built-in compression gauge are used to seal:-

- (i) Raised face and raised face slipon joints.

- (ii) Plain or flat face joints.

- (iii) Vanstone Joints

- (iv) Lapped Joints

- (v) Welded neck flanged joints

GOODSEAL" style with ring gaskets are available in Standard sizes for ANSI B I6.5, flanges in Petrochemical and Reinery piping in accordance with API 601 in all sizes and pressure ratings covered by these Standards. This type of gaskets is also available in Standard sizes to MIL-G21032, MIL-G-16265 DIN specifications. Material constructions are AISI Type SS winding and asbestos Non-Metalic filler, GGP/WR gaskets are available on special order with a choice of any meta winding and Non-Metalic fillers. Special orders with a choice of any metal winding and Non-Metalic fillers, can also be executed.

Designed for standard manhole cover assemblies, these gaskets:-

GOODSEAL Style GMW & GMWC Gaskets are available in a wide variety of designs to meet specific requirements. They are manufactured in three ranges of operating pressures and for almost all makes of boilers and auxiliary equipment. They are available in thicknesses of .175" or .250" flange width of 1/2", 3/4"/ 13/16", 15/ 16" or 1 ¼" and either oval, or abround or round in shape.

GOODSEAL Style MW Gaskets are manufactured of AISL Type Stainless Steel and Asbestos unless otherwise specified [for special orders.] In ordering special "GOODSEAL" Style GMW Gaskets, it is necessary to give complete information, including temperature and pressure, plus a sketch or blueprint of cover assembly. If possible, include a sample gasket or template with the order.

The style WRI gasket has both a solid and outer metal ring. The inner ring prevents inward distortion of the GOODSEAL element and fills any void between flanges from the "Seal" element to the bore of the flange. Generally the inner ring material is the same as the winding metal, [however carbon steel is sometimes specified to reduce costs.] Note: These are not stock items, but are available on special orders.

The most popular style for heat exchangers and foremost large diameter applications. The choice of style is governed by temperature and operating conditions. Asbestos mill board is normally used as filler. Some applications may require compressed asbestos, metal or teflon. For corrosive conditions a choice of jacket metal, is available. There is practically no diameter limitations with greater compressibility and resilience than similar solid metal gaskets. GOODSEAL gaskets provide even support and also, the outside lap helps to prevent excessive distortion of light weight flanges, std., gasket metal thickness various from 0.015" to 0.020".

GWP ORGWRP GASKETS GOODSEAL gaskets may be furnished with partitions for shell and tube heat exchangers. Partitions are normally of double jacketed construction (same metal as winding) with a soft asbestos filler. Partitions are attached to the winding with soft solder. For Special Applications partitions can be attached by silver solder or tack welding. These are wound gaskets for shell and tube heat exchangers with TEMA Flanges. The partitions are furnished double jacketed asbestos filled or plain solid metal. Accurately made to close tolerances, these gaskets are a NIP speciality. We welcome your inquiry on any size

Certain applications which require GOODSEAL gaskets with outer rings have space limitations which preclude the use of a solid metal ring because of minimum width requirements. In these cases NIP can furnish an outer "guide" made entirely of spiral metal windings. This "guide" serves the same basic purpose of a solid metal ring; Compression Limitations and Centering Device. Normally furnished in the same metal as the element in widths of ¼" or less.

Style W gaskets are winding only, no inner or outer rings. Used in thousands of different applications, they may be furnished in many different sizes and thickness.

Style W gaskets are made in standard sizes to fit:

Material is 304 Stainless Steel and Asbestos (unless speciied otherwise, standard thickness is .125".) GGP-RTJG GOODSEAL metal ring joint gaskets are widely used where high pressure and high temperatures are involved. The design of gasket matching taped groove results in a high sealing force as flange bolts are tightened GOODSEAL ring joint gaskets are manufactured to API STD. 6A, NIP carries a large stock of oval and octagonal ring soft iron(D) SS 304, SS316, 4-6% Ch.

These GOODSEAL gaskets are available to replace oval or octagonal metal gaskets in ring-joint flange faces if required to replace the WR-RJ gasket, compared to ½" to ¾" required with conventional ring gaskets; therefore, WR-RJ gaskets are replaced easier and quicker, especially where there is close manifolding of the piping.

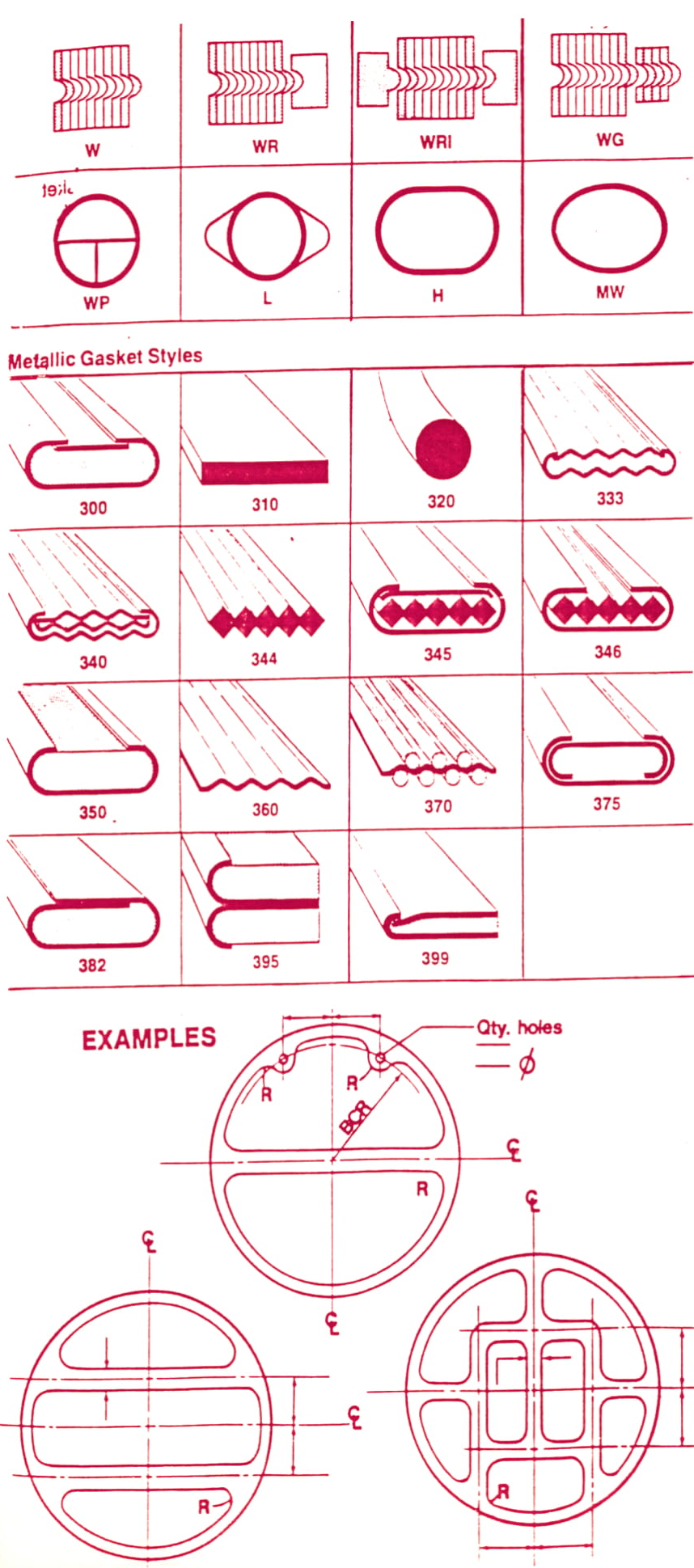

GOOD SEAL Gasket Styles and Shapes

This speciication, developed by the American Petroleum Institute covers double jacketed corrugated gaskets and spiral wound gaskets for use in steel flanges with raised-faces as described in ANSI-B16.5 and API-605. Spiral wound gasket sizes are listed from 1/2" through 24" nps for 1501b through 1500/lb flanges and from 1/2" through 12" for 2500/lb flanges.

For flanges from 26” through 60” nps in 75, 150 and 300/lb pressures.

A broad speciication covering steel pipe flanges and flanged fittings in a variety of gaskets are available to fit these flanges.

A speciication covering large diameter flanges in sizes from 22" to 36" nps, pressures from 300 to 900/lbs for wound gaskets.

A Government speciication covering spiral wound gaskets for 150# through 600# Navy flanges. Sizes differ from API601 on both ID and OD in some cases. Special requirements may apply other sizes.

A Government speciication covering spiral wound gaskets for the Navy and Defence Department for 150/lb through 2500/lb pipe line flanges. Sizes differ.

Information needed to fill an order: